- DIN EN ISO 2768 MK FULL

- DIN EN ISO 2768 MK SOFTWARE

- DIN EN ISO 2768 MK CODE

- DIN EN ISO 2768 MK PC

- DIN EN ISO 2768 MK PLUS

DIN EN ISO 2768 MK SOFTWARE

The software functions as a game engine that installs itself as an extension of the original game, adding core functionality such as networking and GUI rendering while exposing the original game's engine functionality through a scripting language.

DIN EN ISO 2768 MK CODE

Multi Theft Auto is based on code injection and hooking techniques whereby the game is manipulated without altering any original files supplied with the game.

DIN EN ISO 2768 MK PC

It is a unique modification that incorporates an extendable network play element into a proprietary commercial single-player PC game. Multi Theft Auto (MTA) is a software project that adds network play functionality to Rockstar North's Grand Theft Auto game series, in which this functionality is not originally found.

DIN EN ISO 2768 MK FULL

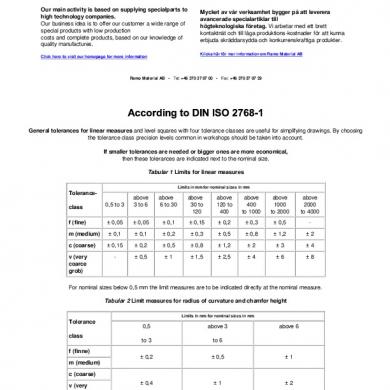

The burr size is measured according to DIN 6785 (total length measured over the burrs, must be within the permissible tolerance).Mtasa-blue - Multi Theft Auto is a game engine that adds full network multiplayer functionality to Rockstar North's Grand Theft Auto game series, in which this functionality is not originally found Del HMS, dokumentasjon og kvalitet Del Tegning og tegningslesing. This web include ISO 2768-General tolerances for linear and angular dimensions. GENERAL TOLERANCES FOR LINEAR AND ANGULAR DIMENSIONS (DIN ISO 27T1). This also applies to general processing characters in or on the title block. Variations on dimensions without tolerance values are according to DIN ISO 2768- mk. Unless otherwise defined, turning parts can have rotary burrs on their end faces (flat surfaces).

DIN EN ISO 2768 MK PLUS

The parts are shafts and couplings and have to fit bearings so I know some of the tolerances are going to be plus and some are minus. Parts made of low-alloy materials are lightly preserved before shipping. DIN ISO 2768 mk tolerances I do not have a full copy of the DIN but I do have some notes and a brief discription of how the tolerances are supposed to work but I still dont quite understand it. technical cleanliness (including burrs and brows)Īll workpieces are commercially cleaned. It is pointed out that a slight error rate may have to be expected when using statistical methods for determining the part quality. The process capability should be able to be demonstrated using the usual statistical methods. In series production, the product quality is checked by spot checks, unless a 100% inspection has been explicitly agreed. If a finer surface roughness is required, this can be achieved by additional processing steps such as grinding or polishing.īasically, the goal is to achieve zero defects. If a free of burrs drill hole transition is required, the chamber size is not defined.ĬNC production achieves surface roughnesses of Ra 1.6 (N7) for turning and miling parts. To all non-dimensioned workpiece edges the following tolerances apply: Outer edges - 0.2 mm / inner edges + 0.4 mm, see DIN ISO 13715.Įdge descriptions such as "sharp-edged free of burrs", "sharp-edged" and "free of burrs" are assumed to be according to DIN 6784 ☐.05 mm, meaning there may be both a minimal material removal and minimal burr.įor example, cross drilled holes can have a burr of max ☐.1 mm.

For drives, screw heads and screw lengths, the tolerances are according to ISO 4759 or the respective, corresponding product standard. Significant deviations or other additional requirements can affect the production and the calculated price. General Tolerances ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f - fine, m - medium, c - coarse, v - very coarse). Additional requirements contained in the drawing are considered for production. If no technical drawing is available production is carried out according to the defined ISO 2768 tolerance range. Select the tolerance field based on the narrowest tolerance of the product. Dimensional tolerances / Form- location- and orientation tolerances Internal thread plain / with surface coating: Tolerance 6-HĮxternal thread with surface coating: Tolerance 6-hĮxecution optionally cut, turned, grooved, rolled, milled or whirled The workpiece can warp, whereby the defined position tolerances can not be guaranteed or simply can not be produced. It should be noted that parts with too thin walls, made of materials with low strength, can have an impact on the manufacturing process.

0 kommentar(er)

0 kommentar(er)